Decoding the Business Benefits of Additive Manufacturing

Introduction: Additive manufacturing (AM) is an innovative production method that's redefining the parameters of industrial operations. This article delves into the nuances of this groundbreaking approach, its potential impact on business models, and the opportunities it presents for growth-oriented enterprises.

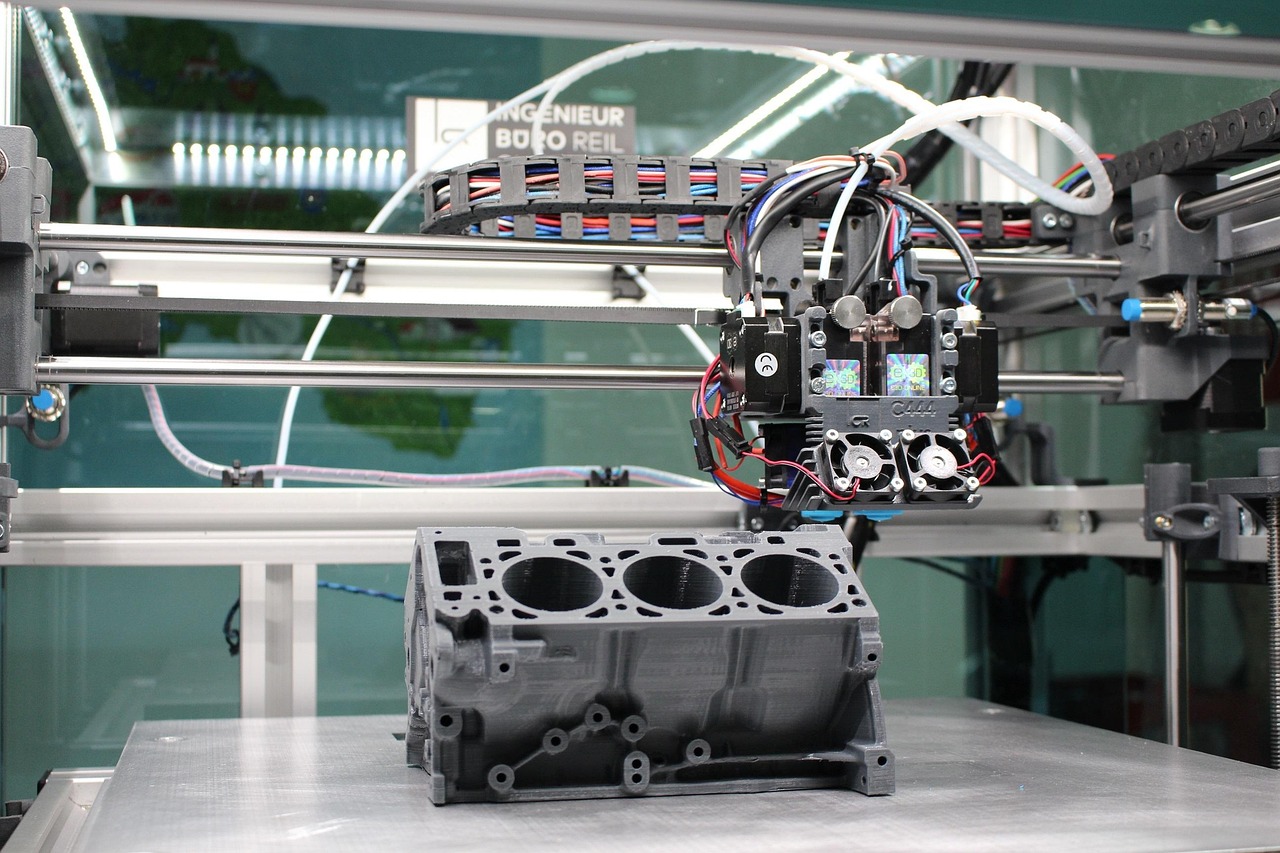

A Primer on Additive Manufacturing

Additive manufacturing, often referred to as 3D printing, is a process wherein products are created by adding materials layer by layer, as opposed to traditional methods that involve cutting or drilling from a larger piece. The technique was first introduced in the 1980s, and it has since evolved to include a diverse array of materials including metal, plastic, and even concrete. With its promise of customization, speed, and reduced waste, AM has captured the attention of industries worldwide.

Implications for Business Models

The impact of additive manufacturing on business models is profound. It shifts the production paradigm from mass manufacturing to customized production, enabling businesses to create products tailored to individual customer needs. This not only enhances customer satisfaction but also reduces waste produced from unsold goods. Furthermore, AM reduces the need for physical inventory, as digital designs can be stored and produced on demand, leading to significant cost savings.

The Role of Additive Manufacturing in Current Business Trends

Additive manufacturing aligns with several prevalent business trends. First, it caters to the growing demand for personalization, as companies can easily modify digital designs to meet specific customer requirements. Second, it supports the trend toward sustainability, as AM uses resources more efficiently and generates less waste than conventional manufacturing methods. Lastly, in a world increasingly dominated by digital technologies, AM embraces digitalization, relying on computer-aided design (CAD) software and 3D scanners.

Challenges and Opportunities

Despite its benefits, additive manufacturing comes with challenges. High startup costs, technological complexity, and regulatory issues can pose hurdles. However, these challenges also present opportunities. For instance, businesses that invest in AM can gain a competitive edge by offering unique, high-quality products. Additionally, with ongoing advancements in technology, the cost of AM equipment is expected to decrease, making it more accessible to a wider range of businesses.

The Future of Additive Manufacturing

The future of additive manufacturing looks promising. With advancements in technology and increasing adoption across industries, AM is poised to become a key driver of industrial innovation. Its potential to disrupt traditional manufacturing processes and supply chains could lead to a new era of efficiency, customization, and sustainability in production.

Practical Insights

- To capitalize on the benefits of AM, businesses should start by understanding their customer needs and how AM can meet these needs.

- It’s essential to invest in employee training to effectively implement and operate AM technology.

- Businesses should also consider partnering with AM experts or service providers to navigate the technological complexities and regulatory landscape.

- To stay competitive, businesses should keep an eye on the latest developments in AM technology and consider how these could be incorporated into their operations.

In conclusion, additive manufacturing presents enormous potential for businesses willing to embrace this innovative production method. While there are challenges to overcome, the benefits of customization, efficiency, and sustainability make AM a game-changer in the industrial world. By understanding the implications of AM, businesses can strategically position themselves to thrive in the evolving industrial landscape.